◆擠壓絲錐是利用金屬塑性變形原理而加工內螺紋的一種新型螺紋刀具,擠壓絲錐擠壓內螺紋是無屑加工工藝,特別適用于強度較低、塑性較好的銅合金和鋁合金,也可用于不銹鋼和低碳鋼等硬度低、塑性大的材料攻絲,壽命長。

◆定義:

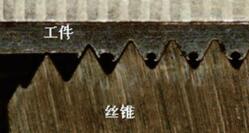

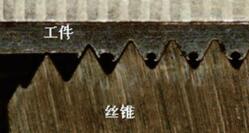

是一種加工內螺紋的刀具,沿軸向開有溝槽。也叫螺絲攻。絲錐根據其形狀分為直槽絲錐, 螺旋槽絲錐和螺尖絲錐。直槽絲錐加工容易,精度略低,產量較大。一般用于普通車床,鉆床及攻絲機的螺紋加工用,切削速度較慢。螺旋槽絲錐多用于數控加工中心鉆盲孔用,加工速度較快,精度高,排屑較好、對中性好。螺尖絲錐前部有容削槽,用于通孔的加工。工具廠提供的絲錐大都是涂層絲錐,較未涂層絲錐的使用壽命和切削性能都有很大的提高。

◆特點:

用擠壓絲錐擠出的螺紋表面光潔度高,螺紋的金屬纖維不斷裂,并在表面形成一層冷硬層,可提高螺紋的強度和耐磨性。它從根本上解決了攻絲的排屑困難問題,因無屑,更有利于螺紋的裝配。在電子,塑料行業應用廣泛。

◆用途:

供加工螺母或其他機件上的普通內螺紋用(即攻絲).機用絲錐通常是指高速鋼磨牙絲錐,適用于在機床上攻絲;手用絲錐是指碳素工具鋼或合金工具鋼滾牙(或切牙)絲錐,適用于手工攻絲。

◇Extrusion tap is by using the theory of metal plastic deformation and machining internal thread of a new type of thread tools, thread in the extrusion tap extrusion is a chipless machining process, especially suitable for the low strength, good plasticity, copper alloy and aluminum alloy can also be used for stainless steel and low carbon steel hardness is low, the large plastic material such as tapping, long service life.

◇Low definition:Is a kind of machining internal thread cutting tools, have grooves along the axial direction. Also called a tap. Tap according to its shape can be divided into straight slot tap, spiral tap and screw tap. Slightly less straight flute tap easy processing, precision, larger output. Commonly used in ordinary lathe, drilling and tapping machine of screw thread processing, cutting speed is slow. Spiral tap drilling blind holes with more used in nc machining center, processing speed, high precision, good chip removal, good to neutral. Tap screw tip anterior yu-jong cutting groove, used for hole processing. Tool factory provide tap tap are mostly coating, less coating tap service life and cutting performance are greatly improved.

◇Low characteristic:With extrusion tap extrusion screw thread surface finish high, threaded metal fibre

Don't break, and form a layer of cold hard layer on the surface, can improve the thread strength and abrasion resistance. It fundamentally solves the tapping of chip removal difficult problem, because there was no crumbs, more conducive to screw assembly. Widely used in electronics, plastics industry.

◇Low usage:For processing on the nuts or other parts of ordinary female with (that is, tapping). Machine tap is usually refers to the high speed steel grinding taps, suitable for tapping on machine tools; Hand tap refers to carbon tool steel or alloy tool steel rolling teeth (or incisor) tap, suitable for manual tapping.

擠壓絲錐: 設計原理、優缺點

Extrusion tap: design principles, advantages and disadvantages

擠壓絲錐是一種先進的無屑成型螺紋加工刀具,加工后螺紋精度高,被廣泛應用在汽車、航空、電子等精工行業。

由于擠壓成型無切屑干擾,因此加工螺紋精度可高達4H,螺紋表面粗糙 度可達Ra0.3左右。 度可達Ra0.3左右。

用切削絲錐加工的螺紋的金屬組織纖維是間斷的,而擠壓螺紋的金屬組織纖維則是連續的。因此,擠壓螺紋強度較之切削螺紋可提高30%左右。

此外,由于擠壓導致的冷作硬化現象,螺紋表面硬度較之芯部可提高40%-50%,同時螺紋表面的耐磨性也得到極大提高。

擠壓絲錐無切削刃、無容屑槽、絲錐強度高,通常不會出現崩刃現象。此外,擠壓絲錐較之一般切削絲錐(比如螺旋槽絲錐)壽命可提高3倍以上,攻絲速度也會有較大提高。但是,擠壓絲錐也有其局限性,具體體現在以下兩個方面:

1、絲錐規格

由于是擠壓成型,需要較高的“擠壓力”,因此,擠壓絲錐普遍制成小規格絲錐,一般M12以下(常用規格為M3-M8)。

2、底孔直徑

一般切削絲錐底孔尺寸:D=d1-P。以M16×2為例,底孔尺寸D=16-2=14。

然而,擠壓絲錐則對底孔要求較為苛刻。一般來說可按以下公式計算大致底孔尺寸:

D=d1-0.49P。仍以M16×2為例,底孔尺寸:D=16-0.49×2=15.02

事實上,不同螺紋旋合度及不同材料、不同孔深的推薦的底孔直徑也會不一樣。這點可參看攻絲底孔直徑計算中有關介紹。

Tap is a kind of advanced chipless extrusion molding thread cutting tools, thread after processing of high precision, is widely used in automotive industry, aviation, electron, etc., seiko.

Because of interference without chip extrusion, the thread machining precision can be up to 4 h, the screw thread surface roughness can reach Ra0.3 or so.

With cutting tap thread of metal fibre is intermittent, and extrusion screw metal tissue fiber is continuous. Therefore, the extrusion thread strength than cutting thread can be increased by about 30%.

In addition, the cold work hardening phenomenon, due to extrusion thread surface hardness than the core can be increased by 40% - 50%, thread surface wear resistance have been greatly improved at the same time.

Extrusion tap without cutting edges, no crumbs slot, tap the intensity is high, usually do not appear collapse edge phenomenon. In addition, the extrusion tap than average cutting tap (such as spiral tap) life can be increased by more than 3 times, tapping speed will have improved greatly. But, extrusion tap also has its limitations, embodies in the following two aspects:

1. tap specifications

Is due to the extrusion molding, need higher "extrusion", therefore, extrusion tap tap is generally made from small specification, under general M12 (commonly used specifications for the M3 - M8).

2. the diameter of bottom hole

General cutting tap base hole size: D = d1 - P. M16×2, for example, bottom hole size D = 16-2 = 14.

Extrusion taps, however, the bottom hole is more demanding. In general can be bottom hole size roughly by the following formula:

D = d1-0.49 P. Still M16×2, for example, bottom hole size: D = 16-0.49 ×2 = 0.49

In fact, screw different degree and different materials, different hole deep base hole diameter of the recommended will be different. This can see the tapping of the bottom hole diameter calculation about the introduction.

絲錐與底孔 Tap and bottom hole

|

|

打印當前頁

打印當前頁 放入收藏夾

放入收藏夾 度可達Ra0.3左右。

度可達Ra0.3左右。